|

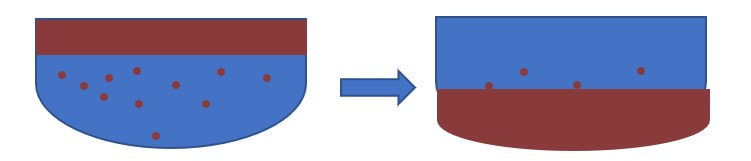

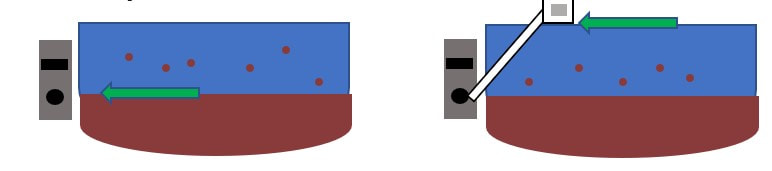

A skimmer device is a dewatering measure that secures to basin outlet structures during construction activity. There are several different available models that are accepted by the Ohio EPA. Some of the commonly used models include Erosion Supply and Company (ESC) Skimmer, Delaware Department of Transportation Skimmer, Faircloth Skimmer, Innovative Applied Solutions (IAS) Skimmer, and the Rymer Marlee Float Skimmer (pictured above). What is the point of using a skimmer? Let’s start with the principle of sedimentation. Sedimentation is the process of sediment particles settling out of a fluid media and precipitating against a solid surface. Stormwater basins hold discharges to allow the suspended sediment to descend in the water column and settle on the floor of the basin. Multi-stage outlet structures are designed to accommodate different levels of water during different rainfall conditions and manage water quality post-construction. However, these structures are not designed to manage the excess sediment that can result from earth disturbance during construction. A skimmer structure connects to the outlet orifice and floats on the surface of the water. When we revisit the concept of sedimentation, that means that the skimmer structure should be intaking the cleanest portion of the water column.This means that less sediment will be traveling through the outlet structure and pipes. This reduces the amount of built-up sediment that can occur in those structures and the amount of maintenance required post-construction. Additionally, this reduces the amount of water that is flowing from the basin directly into streams and other natural waterways. Can’t I just put some rip rap at the basin outfall instead? While rip rap and rock check dams can certainly help to kick some sediment out of runoff, they are not intended to be used as sediment control measures, because a great amount of sediment can still infiltrate through the gaps in the aggregate. Rather, these controls are considered erosion control measures primarily designed to slow the velocity of water. Adding aggregate at the outfall will help to prevent erosion from the concentrated flow exiting the basin but will not replace the need for a skimmer.In addition, if you are not using a skimmer device on the basin and only using controls at the outfall, the basin is being dewatered from a more turbid portion of the water column rather than the cleaner water surface. Therefore, it would take even more work to filter out the sediment at the point of the outfall rather than at the source.Lastly, stormwater pollution prevention plans are specifically designed and engineered to dewater at these elevations and through these devices to meet permit requirements. When plans are not implemented as designed, it can not only present structural complications and present risk to other areas of the project, but it is also a direct violation of the environmental protection regulations in place to safeguard natural ecosystems. How do you design a basin with an appropriate skimmer device? There are several resources that can help with determining the appropriate skimmer for dewatering a basin. One of the best places to start is Ohio EPA’s sediment basin and dewatering compliance tool:https://epa.ohio.gov/static/Portals/35/storm/Sediment+Basin+Compliance+Tool+(Printer+Friendly).xlsx In case you are not familiar, this comprehensive spreadsheet not only helps to ensure that the sediment basins listed in the SWP3 meet the sediment storage and dewatering volume permit requirements, but it also helps to provide guidance and resources for skimmer orifice sizing and dewatering time compliance. Depending on the skimmer model, the spreadsheet will direct you to the manufacturer-specific calculator tools for a simple way to meet design standards. How are skimmers installed and maintained? Installation will depend on the skimmer model and the basin outlet design. However, the skimmer will directly attach the orifice via a coupling. If the basin is a detention pond and has a lower-level water quality orifice that will have gravel and perforated pipe post construction, this will need to be closed off during construction to allow collected water to enter through the skimmer device instead. Maintenance of the skimmer is essential during construction. You will need to ensure that the skimmer stays properly attached to the outlet for the entire duration of the project. Skimmers may also get stuck on the floor of the basin during periods without rainfall. To prevent this from occurring, the skimmer can be elevated on a surface of aggregate, cinder blocks, or bricks. If the skimmer does not seem to be performing optimally, debris and built-up sediment may need to be periodically removed from the orifice plate and screen. Lastly, the area around the outlet and skimmer needs to be free of excess vegetation to prevent clogs and to prevent the skimmer from getting caught in the vegetation and becoming detached or elevated above the surface of the water. Does the skimmer stay on forever? Nope! Once construction is complete and the entire project site is stabilized with vegetation, the skimmer device can be removed and replaced with the permanent outlet structure. BMP Spotlight Example from the Field: Skimmers Branson Staller and his team at SiteWORX have been working at Project Care in Mason, Ohio[BJA2] to construct a new Mercy Hospital facility. During routine inspections, we noticed their team’s prompt basin and skimmer device installation. Having the skimmer on the outlet from the get go has made for more efficient sediment management throughout the project. We interviewed SiteWORX about their committement to sediment and erosion control measures and how using a skimmer has helped with their project construction:

“SWPPP management is an ongoing process through the life of a construction project. Measures such as silt fence & temporary pond skimmers keep the site compliant and help protect the environment. Specifically, the skimmer works by floating at the surface of the water allowing clean water to drain & sediment and silt to settle to the bottom. The skimmer at Mercy Kings Mills has been vital in managing water levels in the micro pool through multiple design changes & regrading of the dry pond to get it to a finished product.” This is a great example of a team taking the time to understand purpose of a sediment and erosion control measure and ensuring that it is in place to do its job right away. Resources: Rainwater and Land Development Manual: https://epa.ohio.gov/divisions-and-offices/surface-water/guides-manuals/rainwater-and-land-development Presentations from Hamilton County Conservation District’s Skimmer Workshop can be found here: https://www.hcswcd.org/skimmers.html

1 Comment

11/29/2023 05:32:26 am

Excellent article. Very interesting to read. I really love to read such a nice article.

Reply

Leave a Reply. |

Details

Urban team BLOGEvery month, the Warren Co SWCD Urban Team dives deep into the world of land development as it relates to stormwater pollution prevention. The blog covers topics like erosion & sediment control best management practices (BMPs), state and local regulations, retention/detention basins, and the conservation of our natural resources. Stay up to date with Development Digest by signing up for WCSWCD Urban eNews!

Categories

All

Archives

July 2024

|

|

|

Contact:PHONE: (513) 695 - 1337

EMAIL: [email protected] HOURS: Monday - Friday 7:30am - 4:00pm (except holidays) Connect:Warren County Soil & Water Conservation District Copyright © 2016

Warren SWCD Privacy Notice. Emails are serviced by Constant Contact. Constant Contact's Privacy Notice. |

RSS Feed

RSS Feed