|

7/3/2024 BMP Maintenance – It Never Stops! A Shout-Out to EGTS Lebanon Compressor Station for a Job Well-DoneRead NowIn an episode of Seinfeld, Newman is quoted as saying “The mail, it never stops Jerry!” The same can be said for maintenance of soil erosion control measures (SECMs) on construction sites; it is a never-ending battle, and it never stops! Your project should have a stormwater team established to ensure that all SECMs are inspected once every 7 calendar days and after every > 0.5-inch rain event per 24-hour period by the end of the next calendar day (per Ohio EPA Construction General Permit requirements). The stormwater and resulting sediment-laden runoff, never stop. So that’s why it’s important that we remain vigilant and maintain the SECMs until the site is stabilized with grass. Warren County SWCD conducts monthly site inspections to help your crew identify failing or missing BMPs to help you stay compliant with the Construction General Permit. When we encounter a project that has done a great job on installation and maintenance of the SECMs, we like to highlight it in our Development Digest for a job well done. This month, we call attention to the Eastern Gas Transmission and Storage, Inc. (EGTS) Lebanon Compressor Station HP project in Clearcreek Township. EGTS boasts a robust environmental compliance division as well as an on-site stormwater team that has been great to work with. The stormwater team has followed the Stormwater Pollution Prevention Plan (SWPPP) to make sure the SECMs are properly installed and maintained. Not only does the site exemplify superb examples of proper SECM installation, maintenance, and an inspection routine, but they also place an emphasis on employee safety. The focus on safety really demonstrates how it’s not just about protecting the environment, but also the people that work together to achieve a common goal. The site is not without its challenges however, with a wetland conveniently nestled between construction areas. The stormwater team has highlighted the importance of protecting the wetland to prevent sediment from filling it in. Most of Ohio’s wetlands have been lost since the days when Ohio was a frontier state. EGTS understands the importance of protecting the ones we still have left. But don’t take my word for it! Hear it from the pros at EGTS: "Eastern Gas Transmission and Storage, Inc. (EGTS) believes responsible environmental management is good business and good for the community, benefiting both customers and its neighbors. EGTS lives by an environmental respect policy using principles that guide its corporate commitment to the environment from the beginning to the end of each day. In closing, we at Warren County SWCD understand that development does not come without risks to the environment, that’s why it’s important that development happens in an environmentally conscious way. So, well done EGTS. May all other construction sites follow your lead!

Questions about BMPs? Call Warren Co SWCD offices at (513) 695-1337

0 Comments

Fast moving water can cause a LOT of damage! Many problems can arise from water flowing at a high velocity. This is especially the case when talking about a high flow rate in concentrated areas such as ditches or swales. Erosion is an issue that can result from the high velocities that may occur in ditches or swales, and so it is important to find ways to mitigate the erosion in the best way possible. Check dams are a great option that can be installed in ditches and swales to decrease the water velocity and in some cases keep sediment from washing downstream.

Check dams are constructed structures built up as a wall in a flow path that serves the purpose of slowing down water velocity. Many check dams consist of 4–8-inch stone and are no higher than 3 feet tall and are constructed along the width of the swale/ditch. Check dams can also be constructed of material such as compost filter sock. As mentioned above, check dams can also serve the purpose of keeping sediment from washing downstream. However, not all types of check dams are good for sediment control. Rock check dams are an effective way to slow down velocity and prevent erosion, however, rock is not an effective method to keep sediment from washing away due to the pore space in the material that sediment can wash right through. Filter socks are designed to keep sediment from washing downstream, and so if the goal is to slow the velocity of the water AND keep sediment in, then a filter sock check dam might be the best option. Maintenance Considerations:

For more information on the design criteria and specifications about check dams, please visit the OEPA Rainwater and Land Development Manual chapter 5.1. For regulations regarding construction and earth disturbance in Ohio please see the OEPA NPDES Construction General Permit. BMP Blast: Silt Fence

What’s the first BMP that comes to mind when you think of construction site sediment control? Chances are you thought of silt fence (SF)! This month, we dig into how this relatively inexpensive practice is used and some common installation pitfalls to avoid. SF is a sediment-trapping barrier comprised of geotextile fabric and support posts. The fence is installed downslope of areas where sheet and rill erosion are expected to occur. Sediment-laden runoff ponds behind the fence and allows for deposition. Although it is a very popular and effective BMP, the Ohio Department of Natural Resources finds that about 75% of SF does not function due to poor installation. Here are some key points to follow:

Do not use SF…

What kind of maintenance does silt fence require?

Assess what caused the failure and make changes to prevent it from happening again. Is there a concentrated flow pointing at the fence? Did someone drive over it? Is the fence sufficiently trenched and compacted? Is the drainage area too big? For more details on the minimum criteria for SF fabric/posts and maximum slope length above SF, please refer to the Ohio Environmental Protection Agency’s (OEPA) Rainwater and Land Development Manual, Chapter 6.3. In an effort to protect the health of our local waterways- rule 901:10-3-11 of the Ohio Administrative Code prohibits solid and liquid waste from being discharged into stormwater runoff. You know the drill- only rain should go down the drain!

Since the risk of stormwater pollution increases with construction activity and land development- the Ohio Environmental Protection Agency’s Construction General Permit (CGP) takes storm drain dumping prohibitions to another level. While the permit largely discusses sediment and erosion control measures, it also lists specific potential pollutants to be mindful of and requires a site-specific Stormwater Pollution Prevention Plan (SWPPP) be written and maintained. Prohibited Discharges

Other Potential Pollutants to Minimize

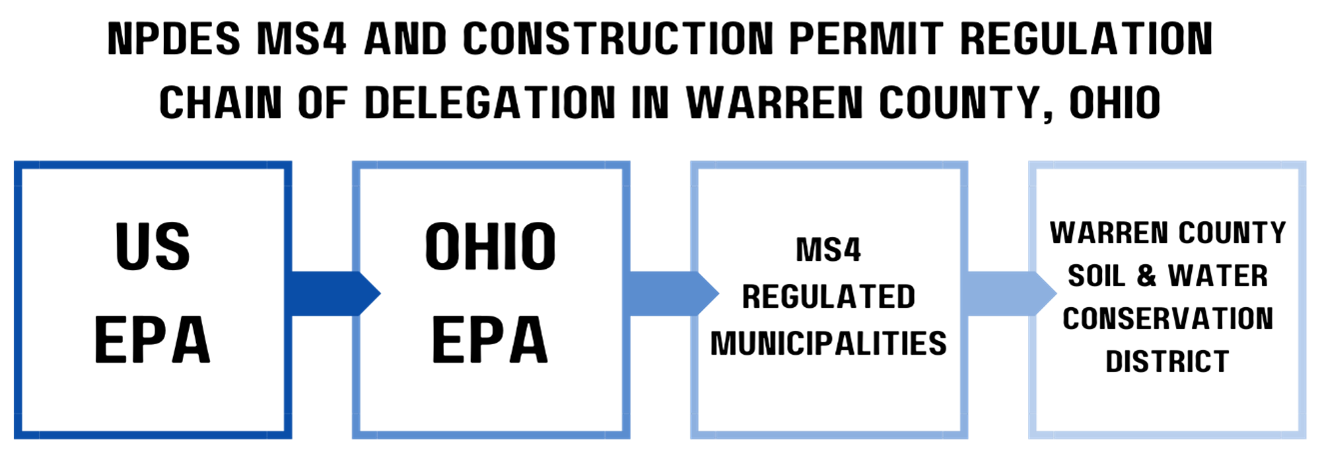

Spills and Unintended Releases Intentionally dumping waste down the drain is certainly prohibited but accidental discharges are just as serious and should be addressed immediately. Keeping up on your periodic site inspections is a great way to identify and address these problems. When possible, locate dumpsters, fueling stations, concrete washout areas, and portable bathrooms away from storm drains and watercourses. For more details on reportable quantities, please refer to this Release Reporting of a Hazardous Substance guide by the Ohio EPA. While an emergency can also constitute a violation, an emergency should be reported immediately to Ohio EPA’s 24-hour spill hotline at 1-800-282-9378 or 614-224-0946. Additional Resources Nearby Sanitary Landfills & Construction and Demolition Debris Facilities Ohio EPA NPDES General Construction Permit (OHC000006) Ohio Rainwater and Land Development Manual In 1948, the Federal Water Pollution Control Act became the first U.S. law to combat water pollution. This act laid groundwork for the establishment of a cornerstone amendment- the Clean Water Act of 1972 (33 U.S.C. §1251 et seq 1972). This reorganization and expansion of the original act required every state to adopt water quality standards to protect, maintain, and improve the quality of the nation's surface waters. The Clean Water Act requires a permit for any discharges from a point source into navigable waters. National Pollutant Discharge Elimination System (NPDES) Permits outline limits on the type and allowable amounts of certain constituents, monitoring requirements, and/or best management practices to mitigate water pollution. Limits and practices are put in place to protect water quality, aquatic life, and public health. The purpose of NPDES permitting is to help provide specific guidance for the overarching goals from the CWA. Types of NPDES Permits:

Municipal Separate Storm Sewer System (MS4) Stormwater NPDES Permit An MS4 is owned by a state, city, town, village, or other public entity designed to collect or convey stormwater (e.g., storm drains, pipes, ditches) and discharge to waters of the U.S. These systems are not a combined sewer overflow system (like in Cincinnati, Columbus, Toledo, etc.), a part of a sewage treatment plant, nor a publicly owned treatment works (POTW). In contrast, stormwater runoff is transported through MS4s, and then discharged, untreated, into local water bodies. To prevent harmful pollutants from entering MS4s and natural waterways, these entities must obtain an NPDES permit and develop stormwater management programs (SWMPs). The 1990 Phase I regulation requires medium and large cities or certain counties with populations of 100,000 or more to obtain NPDES permit coverage for their stormwater discharges. A local example of a Phase I community is Dayton, Ohio. The 1999 Phase II regulation requires small MS4s located fully or partially in urban areas with a population of at least 50,000 and MS4s designated by the permitting authority to obtain NPDES permit coverage for their stormwater discharges. Warren County and several contracted municipalities within the county (i.e., Mason, Deerfield, Lebanon) are regulated under Phase II of the permit. Industrial Stormwater NPDES Permit There are 11 categories of regulated industrial activities that include heavy, manufacturing, coal and mineral mining, hazardous waste treatment, metal scrap yards, transportation facilities, landfills, treatment works, and more. The complete list of facilities and activities subject to industrial stormwater regulations and additional information can be found here. Oil and Gas Linear Transmission Stormwater Certain oil and gas facilities and activities must have CWA section 402 permit coverage to discharge stormwater. Examples include improvements to public roads, conventional petro-refineries, ethanol plants, natural gas utility, commercially/privately owned hotels/RV parks/campgrounds, etc. More information and a more comprehensive list of non-exempt activities can be found here. Ohio did not renew its Oil and Gas Linear Transmission Line permit (OHCG00001) which expired on September 16, 2023. Projects that obtained coverage under the now expired permit shall adhere to the conditions of the permit until the project is eligible to submit a Notice of Termination (NOT). Construction activities which cause a violation of Ohio’s water quality standards may lose exception from NPDES permitting. NPDES Construction General Permit (GCP) Construction activity is considered a point source discharge because specific locations where activity is happening can be identified. This contrasts with non-point source pollutants, which are wide-spread, diffuse sources of pollution across landscapes, so a single point cannot be easily identified. As previously mentioned, federal laws were put into place to prohibit point-source pollutants without an NPDES permit. An NPDES Construction General Permit (CGP) is required for any project that is going to be disturbing one acre or more of land or part of a common plan of development that will ultimately end up disturbing one acre or more. In Warren County, these projects also require an Earth Disturbing Permit (EDP). Earth Disturbing Permit in Warren County

In Warren County, prior to submitting the Notice of Intent (NOI) for the NPDES permit to the Ohio EPA, you must also apply for an EDP, which requires a complete Stormwater Pollution Prevention Plan (SWPPP) review and approval, submission of any necessary stormwater calculations, construction drawings, and the EDP application. This submission page and additional information for specific processes within different municipalities in the counties can be found here. Our urban program specialists at Warren County SWCD are happy to answer any additional questions you may have regarding permit coverage requirement and the NPDES and EDP application process. You can give our office a call at 513-695-1337. Additional Resources US EPA NPDES Stormwater Program US EPA NPDES Technical Resources Earth Disturbing in Warren County Ohio EPA MS4 Permit (OHQ000004) Let’s face it- construction sites can get seriously messy! This month we look at how a designated concrete washout area helps keep your worksite clean and safe while protecting our local waterways from pollution. Concrete washout, also called wash water or slurry, is the waste material created from cleaning out a pump truck, mixer, or anything else that was used to pour concrete. Getting rid of washout is trickier than most construction wastes because it cannot go into a dumpster as-is. Instead, a designated concrete washout area should be provided before cement pouring activities begin so there is no potential for discharge into a stream, ditch, storm drain, or any other water conveyance. After the slurry hardens, it can be disposed of or recycled into aggregate. There are multiple ways to provide a washout area, but the main goal is to have a waterproof pit or container that is easy to locate, use, and maintain. When possible, the area should be at least 50 feet away from storm drains, swales, and waterbodies. Signage and offering more than one washout area are highly recommended for larger developments. (Pictured above are some concrete washout areas seen while conducting our routine monthly inspections.) How does a concrete washout area promote workplace safety?

Concrete washout is a caustic and corrosive waste material with a pH of around 12. If an employee is exposed to washout, they can suffer serious skin irritation, chemical burns, and eye damage. Additionally, concrete washout contains toxic metals like Chromium, Nickel, Vanadium, and Zinc. Exposure in large amounts to these metals can cause long-term damage to the brain, lungs, kidneys, liver, and other important organs. Keeping waste contained to one or two designated areas will help minimize exposures and promote workplace safety. What kind of maintenance does a concrete washout area require?

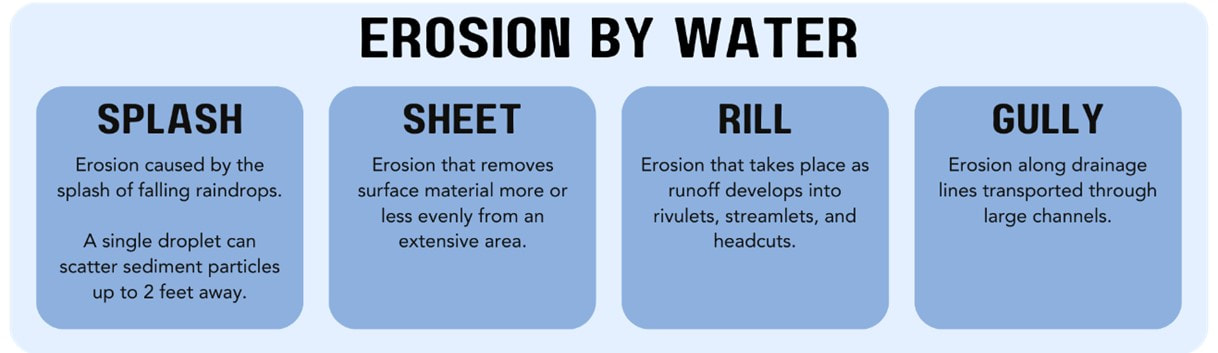

Note: Washout waste is also created when using mortar, plaster, stucco, and grout and should also be disposed of properly. Additional Resources US EPA Concrete Washout Fact Sheet OSHA Concrete Hazards OEPA Rainwater and Land Development Manual Ohio EPA NPDES General Construction Permit (OHC000006) Why is Sediment Considered a Pollutant? We know what you’re thinking… if sediment is a naturally occurring resource found all over the planet, why is it considered a stormwater pollutant? Let’s dig into how sediment erosion affects the health of our lakes, streams, and rivers. Sediment erosion by water is a natural process which shapes the world as we know it. Take the Grand Canyon for example- a natural wonder of the world formed by erosion over millions of years! The key is slow change over a very long period. Human activities that result in large swaths of unstabilized soil (urban development, agriculture, forestry, etc.) accelerate erosion and dump large amounts of sediment into nearby watercourses. According to the United States Environmental Protection Agency (USEPA), “natural erosion produces nearly 30 percent of the total sediment in the United States, accelerated erosion from human use of land accounts for the remaining 70 percent.” While an appropriate amount of suspended and bedded sediments (SABS) is essential to the physical, chemical, and biological integrity of an aquatic ecosystem, an imbalance of SABS can cause serious problems. Too much sediment in the water column can result in death of aquatic life and reduced navigability/recreational enjoyment for humans. Even worse, filtration of drinking water becomes more challenging and therefore more expensive. Imbalanced sediment supply is a leading cause of waterbody impairment in the United States.

How does too much sediment harm water quality and aquatic life? Aquatic organisms that hunt and/or find food using eyesight will be disadvantaged by the cloudy water. Submerged aquatic plants will receive less sunlight, photosynthesize less, and therefore produce less oxygen. Even if there was enough biologically available oxygen for the fish to breathe, they will struggle to do so with clogged gills. Sediment particles will fill crevices in the stream bank which reduces habitat availability. In addition to physically muddying up the water, soil particles introduce toxic pollutants to the watercourse which they bonded with in the landscape (fertilizers, heavy metals, bacteria, pathogens, etc.) Sediment pollution is an interesting topic with several consequences beyond clogging up storm drains. Check out the additional resources below to learn more about how sediment pollution affects our waterways and how you can stay in compliance. Additional Resources USEPA Sediments Overview Ohio Rainwater and Land Development Manual Ohio EPA NPDES General Construction Permit (OHC000006) I’m just clearing. Do I need a permit? The answer is likely yes! In Warren County, an Earth Disturbing Permit (EDP) is required for any project expected to disturb a total area of an acre or more of land. Removing trees with the entire root ball results in land disturbance and exposed soil. Clearing involves the cutting and removal of trees, brush, and other above ground material while grubbing is the removal of roots, stumps, and other material below the existing grade. Regarding an EDP, it does not matter whether the vegetation was naturally occurring or intentionally planted. If you think of this in terms of one tree, it might not seem like a huge concern, but when you think of this type of tree clearing on a large scale (i.e. an acre or more of tree clearing), it can lead to quite a bit of disturbed soil and potential for sediment-laden discharges from the site during rainfall events. Are there any other restrictions for clearing? Yes, depending on when and where you are developing. Tree clearing must not occur between April 1st and September 30th without first coordinating with the Ohio Department of Natural Resources- Division of Wildlife (ODNR-DOW) and the U.S. Fish and Wildlife Service- Ohio Field Office (USFWS-OHFO). Native bat species roost and raise their young in trees all throughout Ohio during this time each year. Unfortunately, all bats in the state are experiencing population decline and have become protected by law in some way. The U.S. Endangered Species Act of 1973 is periodically updated to protect endangered and threatened flora and fauna across the country. Federally endangered species in Ohio include the Indiana Bat (Myotis sodalist) and Northern Long-Eared Bat (Myotis septentrionalis). If your project calls for tree-clearing activities during this five-month window, the ODNR and USFWS will recommend surveys be conducted to determine if the proposed area will negatively impact the bats. If there are no hibernaculum or bats identified during the survey, it may be safe to proceed with tree clearing. Photo credit: Ann Froschauer, USFWS For earth disturbing activities immediately adjacent to surface waters of the state, the Ohio Environmental Protection Agency (OEPA) requires that, if feasible, a 50-foot buffer on either side of the ordinary high-water mark must remain undisturbed. Trees and brush along a water bodies’ edge provides significant stream bank stabilization. If a natural buffer cannot be maintained, land must be temporarily stabilized within two days of the most recent disturbance (if the area will remain idle for more than 14 days) and permanently stabilized within two days of reaching final grade.

Whenever possible, we strongly recommend preserving trees during land development as they prevent erosion, reduce runoff rates, and increase property value. For guidance on tree and natural area preservation, refer to Chapter 7.3 of the Ohio Rainwater and Land Development Manual. Additional Resources USEPA Preserving Natural or Existing Vegetation Fact Sheet Ohio Rainwater and Land Development Manual Ohio EPA NPDES General Construction Permit (OHC000006) BMP Blasts are issued every three months to highlight a sediment and erosion control best management practice. These blasts are designed to provide helpful insight and tips for properly designing, installing, using, and maintaining the control measure. Where and why is inlet protection required? Inlet protection is required on any storm drain at risk of receiving construction site run off. That said, there are limitations to the power of inlet protection. These controls are only designed to manage sediment from a drainage area of one acre or less. If greater than 1 acre of land is draining to one inlet, additional practices such as sediment traps or basins may be required. You may be thinking, “but, I have silt fence and a basin with a skimmer already!” Unfortunately, no one practice is 100% effective when it comes to sediment removal; they each have different strengths and weaknesses. For example, inlet protection has a limited ability to remove silts and clays but can effectively capture larger sand-size particles. The combined effect of each BMP helps to provide maximum sediment removal from storm flows prior to off-site discharge. In other words- perimeter controls, inlet protection, and a basin with a skimmer are likely all required (depending on the site and area of disturbance). Should I have inlet protection listed on my SWPPP? Yes! Inlet protection must be shown on the stormwater pollution prevention plan. While most contractors are familiar with the need for inlet protection, it is important that this is noted on plans to ensure any operator on-site is aware of the requirements and a proper maintenance schedule can be in place. The plan will also show the location all of these “at-risk” inlets so that protection gets installed on all drains and inspectors on-site can identify the location of these areas. Furthermore, it is important to show where these practices will be located in the plan review process to ensure that the drainage area is sized appropriately for the practice. There are certain considerations for placement as well. For example, practices that operate by blocking water from entering storm drains almost completely prevents sediment-laden discharges to entering the conveyance system, but they often result in ponding water. This ponding may be important to consider if these practices will be used on roadways that could flood during heavy rainfall. Are there different types of inlet protection? There are various methods of inlet protection specified in Chapter 6 of the Ohio Rainwater and Land Development Manual. Each method utilizes a combination of stone, wire mesh, and/or geotextile to filter sediment. Alternatively, pre-manufactured inlet protection devices may be used (and reused for the lifetime of the product). What kind of maintenance do inlet filters require?

Additional Resources OEPA Rainwater and Land Development Manual United States EPA Storm Drain Inlet Protection Fact Sheet Ohio EPA NPDES General Construction Permit (OHC000006) Fall-time in southwestern Ohio is simply wonderful; the weather starts to cool down and the trees transform into a lovely autumn palette. Around this time of year, we like to remind developers to continue seeding as much bare soil as possible before winter turns the corner. Soil erosion remains an area of concern for earth disturbing work throughout winter as melting snowfall transports sediment into our local waterways. According to the Ohio Rainwater and Land Development Manual, soil stabilization is the most effective way to minimize sediment erosion from construction sites (over >90%). We mean it when we say seeding and sod installation is music to our ears! Temporary seeding (which must be applied to bare soil where additional work is not scheduled for more than 14 days) may continue until November 1st. Especially through late fall, we recommend monitoring and maintaining seeding efforts until an overall vegetative density of >70% has been achieved. Fall-time seeding species include Rye, Tall Fescue, Annual and Perennial Ryegrass, Creeping Red Fescue, and Kentucky Bluegrass. A layer of mulch (straw, wood cellulose fiber, and/or mulch matting) must be applied during or immediately after seeding. During more favorable seeding times of year, mulching may not be necessary but late fall weather warrants the extra protection. The window for permanent seeding (which must be applied to bare soil at final grade that may be idle for over 1 year) has now closed (March 1st through September 30th). Click here for our guide to dormant seeding during winter months. Traditional permanent seeding efforts may germinate during late fall, but they are unlikely to survive the winter. Spotlight Example from the Field: Seeding Before Winter Ryan Wilms and his team at Cincinnati United Contractors have been working on improvements at Green Bay Packaging in Lebanon, OH. During routine inspections, we noticed their team’s excellent pre-winter stabilization. Having this steep slope stabilized now will set them up for success throughout winter. This also allows for more efficient sediment management throughout the rest of their project. What if temporary/final grading work took longer than expected and you missed the seeding window? Although the disturbed areas cannot be traditionally seeded after the windows have closed, bare soils must be mulched or dormant seeded. For more specific technical guidance and specifications, please review the most recent OEPA Construction General Permit (OHC000006), the Rainwater and Land Development Manual, and the Stormwater Pollution Prevention Plan (SWPPP) for your site. Additional Resources Construction Site Winterization – Development Digest Rainwater and Land Development Manual Ohio EPA NPDES General Construction Permit (OHC000006) Seeding Tables – USDA NRCS |

Details

Urban team BLOGEvery month, the Warren Co SWCD Urban Team dives deep into the world of land development as it relates to stormwater pollution prevention. The blog covers topics like erosion & sediment control best management practices (BMPs), state and local regulations, retention/detention basins, and the conservation of our natural resources. Stay up to date with Development Digest by signing up for WCSWCD Urban eNews!

Categories

All

Archives

July 2024

|

|

|

Contact:PHONE: (513) 695 - 1337

EMAIL: [email protected] HOURS: Monday - Friday 7:30am - 4:00pm (except holidays) Connect:Warren County Soil & Water Conservation District Copyright © 2016

Warren SWCD Privacy Notice. Emails are serviced by Constant Contact. Constant Contact's Privacy Notice. |

RSS Feed

RSS Feed